Other Rubber Products

- Arch Fenders

- Cell Fenders

- Cone Fenders

- Cylindrical Fenders

- D Fenders

- Delta Fenders

- I Fenders

- IV Fenders

- Key Hole Fenders

- M Fenders

- Other Rubber Products

- Polyurethane Products

- Pre Curved Cylindrical Fenders

- PU Foam Fenders & Buoys

- Shear Fenders

- Square Fenders

- Strip or Flat Board Fenders

- Ultra High Molecular Weight Poly Ethylene (UHMW-PE) Pads/ Sheets

- W Fenders

- White or Coloured Non Marking Fenders

- Wing or GD Fenders

Fender Marine also manufacture and export all types of Extruded and Moulded Rubber Products for applications in Automotive Industry like O-Rings, Gaskets, Oil Seals, Lip Seals, Hydraulic Seals, Bushes, Rubber Strips, EPDM Profiles (Solid and Sponges), Silicon Profiles (Solid and Sponge), etc.

PU Foam Fenders & Buoys

- Arch Fenders

- Cell Fenders

- Cone Fenders

- Cylindrical Fenders

- D Fenders

- Delta Fenders

- I Fenders

- IV Fenders

- Key Hole Fenders

- M Fenders

- Other Rubber Products

- Polyurethane Products

- Pre Curved Cylindrical Fenders

- PU Foam Fenders & Buoys

- Shear Fenders

- Square Fenders

- Strip or Flat Board Fenders

- Ultra High Molecular Weight Poly Ethylene (UHMW-PE) Pads/ Sheets

- W Fenders

- White or Coloured Non Marking Fenders

- Wing or GD Fenders

FENDER MARINE PUFoam Fenders & Buoys work equally well in harbors or between vessels. Low hull pressures protect soft-skinned ships. FENDER MARINE combines a Durable, Non-marking finish with Low maintenance, Low reaction and high energy absorptions, No chain/tire net required, Virtually indestructible, Unsinkable design, Non-marking even against white hulls, Maintains safe stand-off distances, Low hull pressures, Wide range of standard and custom sizes, Well proven design and low maintenance and operational cost.

IV Fenders

- Arch Fenders

- Cell Fenders

- Cone Fenders

- Cylindrical Fenders

- D Fenders

- Delta Fenders

- I Fenders

- IV Fenders

- Key Hole Fenders

- M Fenders

- Other Rubber Products

- Polyurethane Products

- Pre Curved Cylindrical Fenders

- PU Foam Fenders & Buoys

- Shear Fenders

- Square Fenders

- Strip or Flat Board Fenders

- Ultra High Molecular Weight Poly Ethylene (UHMW-PE) Pads/ Sheets

- W Fenders

- White or Coloured Non Marking Fenders

- Wing or GD Fenders

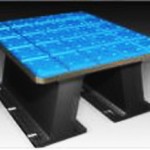

Fender Marine IV type rubber fenders are installed on docks to protect the Docks and Ships from being damaged at the time of berthing. Our rubber marine fender is of large top area, which provides small surface pressure. With high energy absorption and low reaction force, this rubber fender is suitable for ten-thousand-ton docks. The span between two supporting arms is adjustable. It is also available to combine multiple supporting arms. The design compressive deflection is up to 52.5%. The impingement plate adopts UHWPE plate or nylon plate, with low friction coefficient 0.07, which is good for berthing. This marine fender could be installed vertically or horizontally, with no need for supported anchor chain. It is simple and convenient to install, repair and replace

I Fenders

- Arch Fenders

- Cell Fenders

- Cone Fenders

- Cylindrical Fenders

- D Fenders

- Delta Fenders

- I Fenders

- IV Fenders

- Key Hole Fenders

- M Fenders

- Other Rubber Products

- Polyurethane Products

- Pre Curved Cylindrical Fenders

- PU Foam Fenders & Buoys

- Shear Fenders

- Square Fenders

- Strip or Flat Board Fenders

- Ultra High Molecular Weight Poly Ethylene (UHMW-PE) Pads/ Sheets

- W Fenders

- White or Coloured Non Marking Fenders

- Wing or GD Fenders

Fender Marine I type rubber fenders are installed on docks to protect the Docks and Ships from being damaged at the time of berthing. Our rubber marine fender is of large top area, which provides small surface pressure. With high energy absorption and low reaction force, this rubber fender is suitable for ten-thousand-ton docks. The span between two supporting arms is adjustable. It is also available to combine multiple supporting arms. The design compressive deflection is up to 52.5%. The impingement plate adopts UHWPE plate or nylon plate, with low friction coefficient 0.07, which is good for berthing. This marine fender could be installed vertically or horizontally, with no need for supported anchor chain. It is simple and convenient to install, repair and replace.

Square Fenders

- Arch Fenders

- Cell Fenders

- Cone Fenders

- Cylindrical Fenders

- D Fenders

- Delta Fenders

- I Fenders

- IV Fenders

- Key Hole Fenders

- M Fenders

- Other Rubber Products

- Polyurethane Products

- Pre Curved Cylindrical Fenders

- PU Foam Fenders & Buoys

- Shear Fenders

- Square Fenders

- Strip or Flat Board Fenders

- Ultra High Molecular Weight Poly Ethylene (UHMW-PE) Pads/ Sheets

- W Fenders

- White or Coloured Non Marking Fenders

- Wing or GD Fenders

Fender Marine Square & Rectangle type fenders are used for tugs, barges, work boats and pilot boats as side belting and protective fenders against heavy Rubbing, Impact, Brushing and Pushing force. These square type fenders having a higher energy absorption capacity so minimizing the face contact.

Square Fenders are commonly used on vessels as well as small jetties. They are compression molded or Extruded fenders generally used on tug, boats and ships. This type rubber fender is installed on docks to protect the Docks and Ships from being damaged at the time of berthing. The rated deflection of our square rubber boat fender is 40-50 %. According to the reaction force, our square rubber boat fender can be grouped into standard reaction force type and high reaction force type.

|

Product Reference |

Base x Height x D Hollow mm |

R (Ton /m) |

E (Ton-M/m) |

|

SD 150 |

150 x 150 x 75 |

12.4 |

0.62 |

|

SD 200 |

200 x 200 x 100 |

29.8 |

1.11 |

|

SD 250 |

250 x 250 x 125 |

37.3 |

1.73 |

|

SD 300 |

300 x 300 x 150 |

44.7 |

2.49 |

|

SD 350 |

350 x 350 x 175 |

53.0 |

3.39 |

|

SD 400 |

400 x 400 x 200 |

59.8 |

4.44 |

|

Product Reference |

Base x Height x D Hollow mm |

R (Ton /m) |

E (Ton-M/m) |

|

SO 150 |

150 x 150 x 75 |

16.8 |

0.39 |

|

SO 200 |

200 x 200 x 100 |

21.0 |

0.69 |

|

SO 250 |

250 x 250 x 125 |

26.0 |

1.01 |

|

SO 300 |

300 x 300 x 150 |

31.0 |

1.56 |

|

SO 350 |

350 x 350 x 175 |

34.5 |

1.95 |

|

SO 400 |

400 x 400 x 200 |

41.0 |

2.52 |

Pre Curved Cylindrical Fenders

- Arch Fenders

- Cell Fenders

- Cone Fenders

- Cylindrical Fenders

- D Fenders

- Delta Fenders

- I Fenders

- IV Fenders

- Key Hole Fenders

- M Fenders

- Other Rubber Products

- Polyurethane Products

- Pre Curved Cylindrical Fenders

- PU Foam Fenders & Buoys

- Shear Fenders

- Square Fenders

- Strip or Flat Board Fenders

- Ultra High Molecular Weight Poly Ethylene (UHMW-PE) Pads/ Sheets

- W Fenders

- White or Coloured Non Marking Fenders

- Wing or GD Fenders

Fender Marine Can supply Pre-Curved Cylindrical Fenders as per the customer requirements.

Cylindrical Fenders

- Arch Fenders

- Cell Fenders

- Cone Fenders

- Cylindrical Fenders

- D Fenders

- Delta Fenders

- I Fenders

- IV Fenders

- Key Hole Fenders

- M Fenders

- Other Rubber Products

- Polyurethane Products

- Pre Curved Cylindrical Fenders

- PU Foam Fenders & Buoys

- Shear Fenders

- Square Fenders

- Strip or Flat Board Fenders

- Ultra High Molecular Weight Poly Ethylene (UHMW-PE) Pads/ Sheets

- W Fenders

- White or Coloured Non Marking Fenders

- Wing or GD Fenders

a). Cylindrical Fender for Offshore/Jetty.

Cylindrical rubber-dock fender is a type of Cylindrical fender with hollow inside diameter in proportionate with the outer diameter. Generally, the standard proportion / ratios between the outside diameters and the inside diameters are 2:1 and 1. 75:1. These cylindrical fenders are used to clamp upon the quay / jetty for absorbing the shock or impact created by rubbing of the steel of a vessel with the quay. The hollow inside of the fender acts as a spring which gives cushioning effect and the load/shock is dispersed all over the fender, thus protecting the quay and the vessel’s body. Cylindrical fender can be installed horizontally along with chains on either side or at an angle.

Cylindrical fenders are commonly used fenders recommended for all types of application to ensure a safe and linear berthing for the different kind of vessels. Cylindrical fenders are an economical solution to protect most of the berthing structures and offer much ease for installation. With 50% design compressive deflection, this kind of rubber fender can effectively buffer the collision between docks and ships.

FENDER MARINE Cylindrical fenders have with high energy absorption and low reaction force. We are manufacturing our cylindrical fenders by Molding, Extrusion and wrapping methods as per the customer requirements for Offshore and Ships. FENDER MARINE Cylindrical rubber fender is mainly suitable for tugboat and pushing vessel. It can be installed at the bow, side and stern of a ship to push and drag the ship.

FENDER MARINE Cylindrical Rubber fender features low reaction force, less surface pressure, and reasonable energy absorption. Due to its simple shape, this marine fender is easy to install and maintain. It is suitable for all kinds of ships and docks. It has good adaptability for the pitching and rolling of ships during berthing. This rubber fender can be used as the suspended type defense equipment for various docks. As per the requirement of the length of the fender it can be suited in one or more sections/lengths, when there are multiple lengths spigots or connector plugs are used for installation.

D Fenders

- Arch Fenders

- Cell Fenders

- Cone Fenders

- Cylindrical Fenders

- D Fenders

- Delta Fenders

- I Fenders

- IV Fenders

- Key Hole Fenders

- M Fenders

- Other Rubber Products

- Polyurethane Products

- Pre Curved Cylindrical Fenders

- PU Foam Fenders & Buoys

- Shear Fenders

- Square Fenders

- Strip or Flat Board Fenders

- Ultra High Molecular Weight Poly Ethylene (UHMW-PE) Pads/ Sheets

- W Fenders

- White or Coloured Non Marking Fenders

- Wing or GD Fenders

a). DO Fenders.

FENDER MARINE DO Fenders are used for tugs, barges, work boats, and pilot boats as side belting and protective fenders against heavy rubbing, brushing and pushing forces. These DO-Type Fenders having higher energy absorption capacity, thus minimizing the face contact. DO type fenders are commonly used on vessels. They are compression molded or Extruded type. These fenders are used to absorb the berthing energy during mooring or berthing so as to protect the ship and the dock from being damaged. This rubber fender is of moderate reaction force, and higher energy absorption than the cylindrical type fenders. It is easy and convenient to install and change. The width of its bottom is small, so this marine fender can be installed at ship side.

b). DD Fenders.

DD type fenders are commonly used on jetties. They are compression molded or Extruded type. These fenders are used to absorb the berthing energy during mooring or berthing so as to protect the ship and the dock from being damaged. It is suitable for various docks, wharfs, and ship sides. This rubber fender is of moderate reaction force, and higher energy absorption than the cylindrical type fenders. It is easy and convenient to install and change. The width of its bottom is small, so this marine fender can be installed at docks.

Delta Fenders

- Arch Fenders

- Cell Fenders

- Cone Fenders

- Cylindrical Fenders

- D Fenders

- Delta Fenders

- I Fenders

- IV Fenders

- Key Hole Fenders

- M Fenders

- Other Rubber Products

- Polyurethane Products

- Pre Curved Cylindrical Fenders

- PU Foam Fenders & Buoys

- Shear Fenders

- Square Fenders

- Strip or Flat Board Fenders

- Ultra High Molecular Weight Poly Ethylene (UHMW-PE) Pads/ Sheets

- W Fenders

- White or Coloured Non Marking Fenders

- Wing or GD Fenders

Fender marine also manufactures and exports all type of Delta Fender as per the customer requirements.

Fender Marine Delta Fenders are Available in Synthetic & Natural Rubbers, all colours, Long length, etc.

Advantages of Fender Marine Delta Fenders.

- Available in Synthetic & Natural Rubbers.

- Available in all Colours.

- Available in Long Length.

- Minimizes Surface Contact.

- Suitable for all Vessels and Marinas.

- Eassy Mounting.

- Wide range of Applications.

- Cutting and Drilling Services.

W Fenders

- Arch Fenders

- Cell Fenders

- Cone Fenders

- Cylindrical Fenders

- D Fenders

- Delta Fenders

- I Fenders

- IV Fenders

- Key Hole Fenders

- M Fenders

- Other Rubber Products

- Polyurethane Products

- Pre Curved Cylindrical Fenders

- PU Foam Fenders & Buoys

- Shear Fenders

- Square Fenders

- Strip or Flat Board Fenders

- Ultra High Molecular Weight Poly Ethylene (UHMW-PE) Pads/ Sheets

- W Fenders

- White or Coloured Non Marking Fenders

- Wing or GD Fenders

Fender Marine “W” Type Fenders are installed in to the bow and the aft portion of the ocean going tugs, to protect the hull of the vessel, against the damages caused during pushing and Pulling operations/ towages. These fenders are installed in similar manner as those of Key Hole Fenders.

With 50% design compressive deflection, this kind of W – rubber fender can effectively buffer the collision between docks and ships. Our W fenders have with high energy absorption and low reaction force. This type rubber fender is installed on Ship front area to protect the Ships from being damaged at the time of berthing. We can customize marine fenders in accordance with your special requirements for performance and specifications. For instance, the tensile strength ranges from 12MPa to 16MPa.